Join Our Team

Mechanical Engineer in the field of Solid Mechanics with background in constitutive modeling and FEA (MS/PhD)

We are currently seeking a Mechanical Engineer in the field of Solid Mechanics with background in constitutive modeling and FEA. We offer opportunities for you to expand your engineering or scientific knowledge by working on cutting edge research projects collaborating with national laboratories and universities.

Apply NowUndergraduate/Graduate Summer Interns (Software Engineer, Business Developer, Mechanical Engineer)

Four summer intern positions to work on various projects for energy applications.

Apply NowWho we are

Additive Manufacturing Innovations LLC (AM-Innov) was founded in 2017 with the goal of inventing and commercializing products for industrial applications for metal additive manufacturing (AM). We are located in Potsdam, New York.

Our mission

To develop innovative hardware and software solutions for addressing various technical challenges in the field of metal AM technology, and thereby advance the technology to meet the needs of next-generation applications

Our vision

To make AM technology's accessibility to small and medium manufacturing companies.

Projects

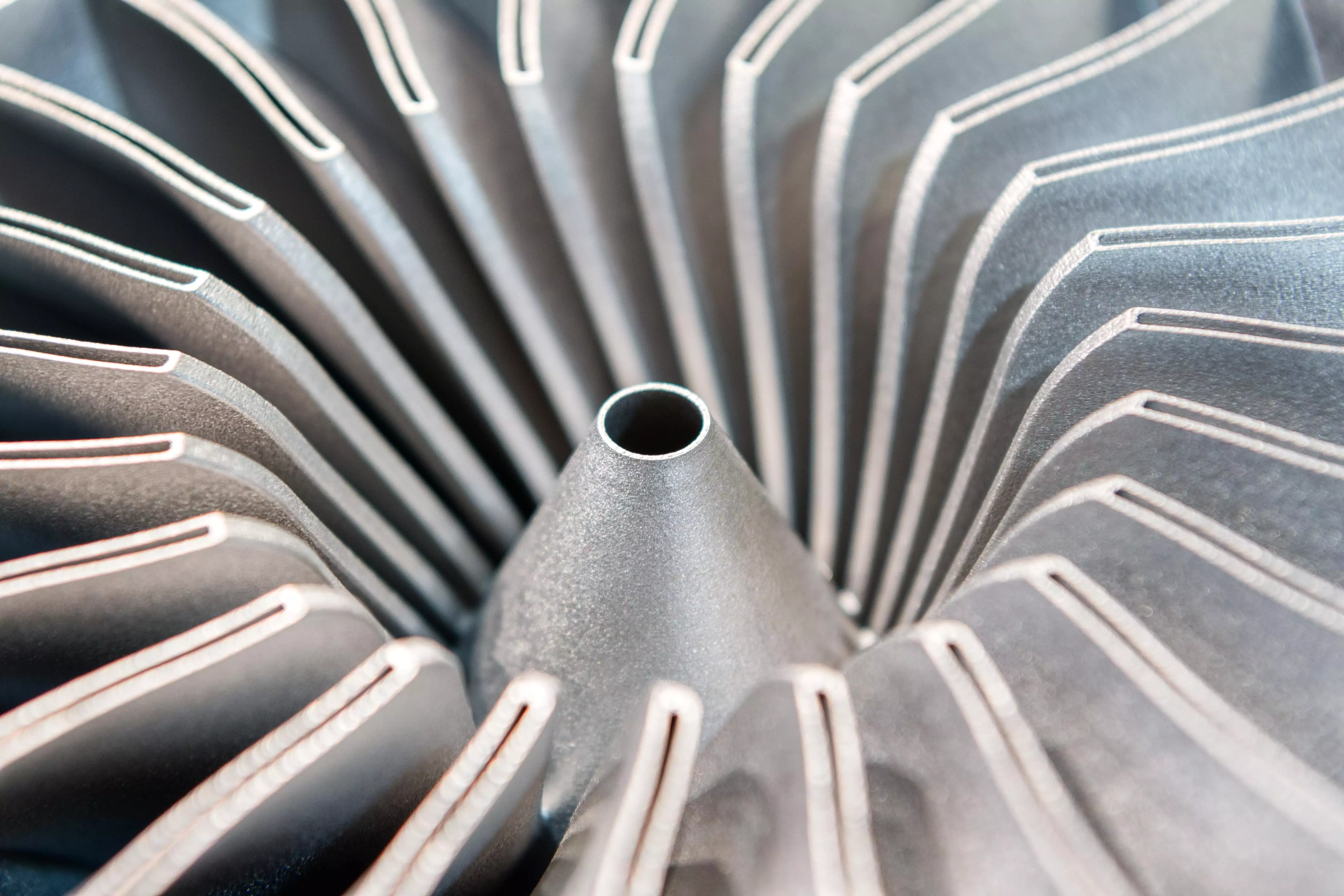

Simulation of Additive Manufacturing of Metals

((A project in collaboration with Prof. Achuthan's group at Clarkson University)

Fast Finite Element (FE) framework with selective mesh coarsening to simulate additive manufacturing processes was developed. The new method allows unlimited flexibility to choose the level of mesh coarsening during the building process. The simulation shows stress formation along build direction (Z) during the printing process of a cylinder (200 layers) using Direct Metal Deposition (DMD) technique. Implemented in ABAQUS

Read More